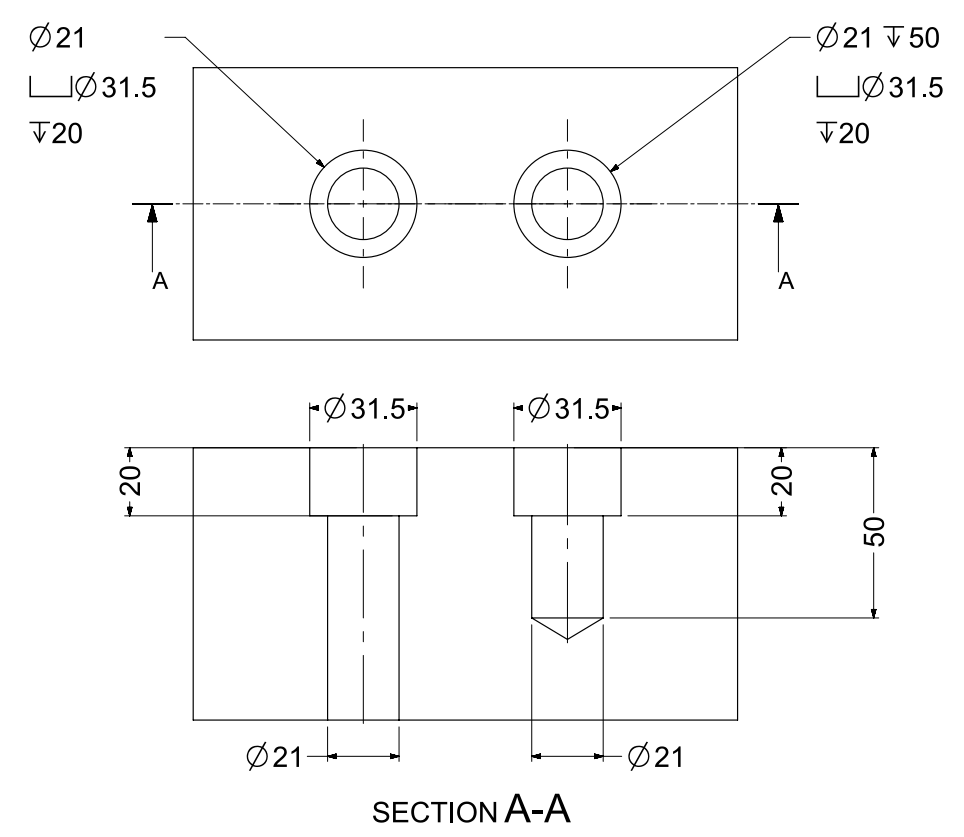

Counterbore Callout Drawing . The depth number and the diameter symbol are also. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. Learn what a counterbore is, how to dimension and measure it, and how to distinguish it from a countersink or a spotface. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. See examples of counterbore symbols and.

from samhakes.com

Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. The depth number and the diameter symbol are also. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. See examples of counterbore symbols and. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. Learn what a counterbore is, how to dimension and measure it, and how to distinguish it from a countersink or a spotface.

Types of Holes The Complete Guide The Engineer's Bible (2023)

Counterbore Callout Drawing See examples of counterbore symbols and. The depth number and the diameter symbol are also. Learn what a counterbore is, how to dimension and measure it, and how to distinguish it from a countersink or a spotface. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. See examples of counterbore symbols and. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances.

From www.xometry.com

Spotface vs. Counterbore Holes in Machining Differences and Uses Xometry Counterbore Callout Drawing The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. See examples of counterbore symbols and. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes. Counterbore Callout Drawing.

From www.madearia.com

What are the different types of holes in engineering? Counterbore Callout Drawing Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. See examples of counterbore symbols and. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. Learn what a counterbore is, how to. Counterbore Callout Drawing.

From www.engineersrule.com

Tips and Tricks for Defining and Organizing Hole Callouts in SOLIDWORKS Counterbore Callout Drawing This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. Learn what a counterbore is, how to dimension and. Counterbore Callout Drawing.

From www.wisc-online.com

Countersink Example3 OER Counterbore Callout Drawing This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. See examples of counterbore symbols. Counterbore Callout Drawing.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Counterbore Callout Drawing This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. See examples of counterbore symbols and. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. The depth number and the diameter symbol are also. The counterbore. Counterbore Callout Drawing.

From www.ptcusercommunity.com

Calling out Counter bores in Drawings. PTC Community Counterbore Callout Drawing The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. See examples of counterbore symbols and. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface. Counterbore Callout Drawing.

From www.javelin-tech.com

How to Combine SOLIDWORKS Hole Callouts Part 2 Counterbore Callout Drawing Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. See examples of counterbore symbols and. Learn how to identify and interpret notes,. Counterbore Callout Drawing.

From mavink.com

Counterbore Chart Counterbore Callout Drawing Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on. Counterbore Callout Drawing.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Counterbore Callout Drawing The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. See examples of counterbore symbols and. The depth number and the diameter symbol are also. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. This process ensures a smooth and accurately located mounting surface for fasteners such. Counterbore Callout Drawing.

From www.engineersrule.com

Tips and Tricks for Dimensioning and Managing Hole Callouts with MBD Counterbore Callout Drawing The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. Some examples include thread specifications, surface finishes, surface quality, and. Counterbore Callout Drawing.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Counterbore Callout Drawing Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. See examples of counterbore symbols and. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the. Counterbore Callout Drawing.

From ar.inspiredpencil.com

Standard Countersink Hole Counterbore Callout Drawing The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. Learn what a counterbore is, how to dimension and measure it, and how to distinguish it from a countersink or a. Counterbore Callout Drawing.

From www.3dhubs.com

How to prepare a technical drawing for CNC machining 3D Hubs Counterbore Callout Drawing The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. The counterbore symbol is used on a drawing. Counterbore Callout Drawing.

From www.eng-tips.com

Questionable true position callout Drafting Standards, GD&T Counterbore Callout Drawing The depth number and the diameter symbol are also. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. Learn how to identify and interpret. Counterbore Callout Drawing.

From www.eng-tips.com

THREADED HOLE WITH COUNTERBORE CALLOUT Aeronautic & Space engineering Counterbore Callout Drawing The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. See examples of counterbore symbols and. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Learn how to identify and interpret notes, specifications, and. Counterbore Callout Drawing.

From lectures-nd-notes.blogspot.com

Lecture Notes Engineering Drawing Part 4 Counterbore Callout Drawing The depth number and the diameter symbol are also. The spotface is typically achieved by cutting a shallow counterbore that is just deep enough to make the surface flat. Learn what a counterbore is, how to dimension and measure it, and how to distinguish it from a countersink or a spotface. The counterbore symbol is used on a drawing to. Counterbore Callout Drawing.

From sadboxabc.blogspot.com

카운터 싱크 & 카운터 보어 정의와 표기법 INSIDE INSIGHTS Counterbore Callout Drawing This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. The counterbore symbol is used on a drawing to indicate that a counterbore hole feature is required. The ‘⌴’ symbol is used to. Counterbore Callout Drawing.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts Counterbore Callout Drawing The depth number and the diameter symbol are also. This process ensures a smooth and accurately located mounting surface for fasteners such as bolts, nuts, and washers. Learn how to identify and interpret notes, specifications, and callouts for holes and other machining processes on a print. The ‘⌴’ symbol is used to indicate a counterbore hole on engineering drawings. The. Counterbore Callout Drawing.